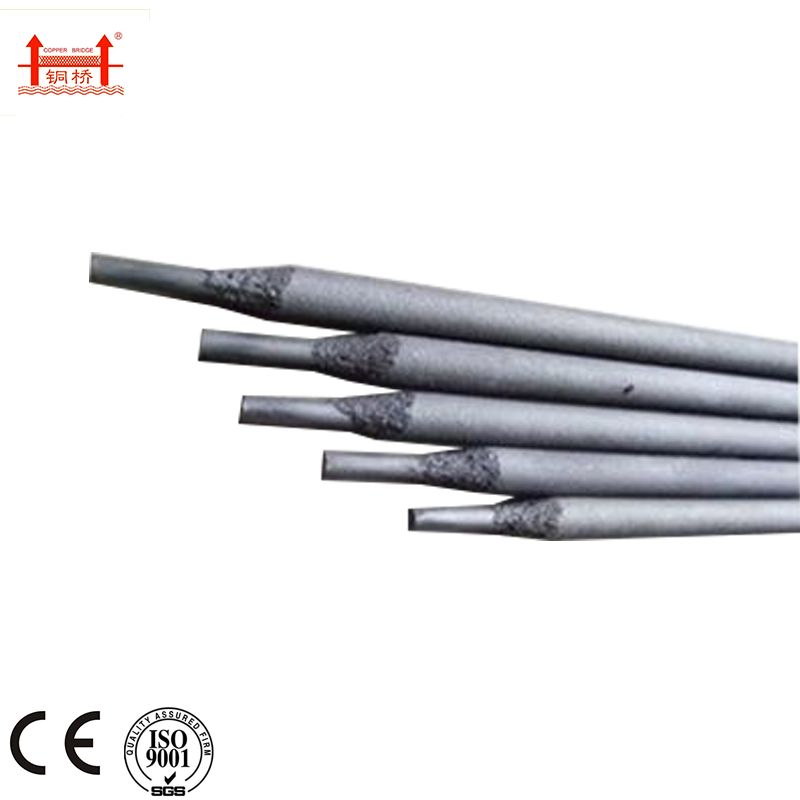

Nā Electrodes Kuhiliʻole CB-A102

Hoʻohana ʻia ka hoʻohana ʻana o ka electrode stainless steel

1. chromium kuhiliʻole kila i kekahi corrosion kū'ē (oxidizing acid, organic waika, cavitation), wela a me ka lole pale.Hoʻohana maʻamau i nā mea kanu mana, kemika, ka ʻaila a me nā mea lako ʻē aʻe.ʻO Chromium stainless steel maikaʻi ʻole weldability, pono e hoʻolohe i ke kaʻina hana kuʻi, nā kūlana mālama wela a me ke koho ʻana o ka electrode kūpono.

2. CR-13 kila kuhiliʻole i oi aku ka paakiki ma hope o ka wiliwili ana a me ka maʻalahi e hana māwae.Inā hoʻohana ʻia ke ʻano like o ka chromium stainless steel electrode (G202, G207) no ke kuʻi ʻana, pono e hoʻomaʻamaʻa mua ʻia ma luna o 300 ° C a hoʻomaha ʻia ma kahi o 700 ° C ma hope o ke kuʻi ʻana.Inā ʻaʻole hiki ke hoʻokō ʻia ka hoʻopaʻa ʻana i ka wela ma hope o ka weld, a laila ke koho ʻia ʻo chromium-nickel stainless steel electrode (A107, A207).

3. Chromium 17 stainless steel, i mea e hoʻomaikaʻi ai i ka corrosion resistance a me ka weldability a hoʻonui i ka nui kūpono o nā mea paʻa e like me Ti, Nb, Mo, etc. , ʻoi aku ka maikaʻi o ka weldability ma mua o ka chromium 13 stainless steel.Ke hoʻohana ʻia ke ʻano like o ka chromium stainless steel electrode (G302, G307), pono e hoʻomaʻamaʻa mua ʻia ma luna o 200 ° C a hoʻonāuki ʻia ma kahi o 800 ° C ma hope o ke kuʻi ʻana.Inā ʻaʻole hiki ke hoʻomaʻamaʻa ʻia ka welding, a laila ke koho ʻia ʻo chromium-nickel stainless steel electrode (A107, A207).CR-NI stainless steel electrode he maikaʻi corrosion kū'ē a me ka oxidation kū'ē, hoʻohana nui 'ia i ka oihana kemika, fertilizer, petroleum, lāʻau mīkini hana.

4. 0 a ma lalo hiki ke hoʻohana no nā kūlana āpau.

5. 0 a ma luna no ka hoʻoheheʻe palahalaha a me ka hoʻopili ʻana i ka fillet.

6. ʻO ka chromium-nickel stainless steel coating he titanium-calcium type a haʻahaʻa hydrogen type.Hiki ke hoʻohana ʻia ke ʻano calcium titanate i ka AC a me DC, akā ʻo ke komo ʻana o ke kuʻi ʻana o ka pāpaʻu AC, ʻoiai maʻalahi ke ʻulaʻula, no laila e hoʻohana ai i ka mana DC.Anawaena

7. Pono e maloʻo ka electrode, e maloʻo ke ʻano titanium-calcium ma 150 ° C no 1 hola, a e maloʻo ka ʻano hydrogen haʻahaʻa ma 200 ° C a 250 ° C no 1 hola (ʻaʻohe hoʻomaloʻo hou, inā ʻaʻole. ua maʻalahi ka uhiʻana a me ka peel off), pale i ka electrode coating e hoʻopili i kaʻaila a me nā lepo'ē aʻe, iʻole e hoʻonui i ka carbon content o ka weld a pili i ka maikaʻi o ka welding.

8. I mea e pale ai i ka corrosion ma waena o nā maka i hana ʻia e ka hoʻomehana ʻana, ʻaʻole nui ka nui o ke kuʻi ʻana, ʻaʻole i emi iho ma mua o ke kalapona kila electrode e pili ana i 20%, ʻaʻole lōʻihi ka lōʻihi o ka ARC, ka hoʻomaloʻo wikiwiki ʻana ma waena o nā papa, e kūpono i ka bead haiki. .

| Hoʻohālike | GB | AWS | Anawaena(mm) | Ke ʻano o ka uhi ʻana | ʻO kēia manawa | Hoʻohana |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | ʻAno Lime-titania | DC | Hoʻohana ʻia no ka wili ʻana i ka corrosion-resistant 0cR19Ni9 a me 0Cr19Ni11Ti nā hale kila kila ma lalo o 300︒C |

Huina Kemika o ka metala i waihoia

| Hoʻohui Kimia o ka metala i waiho ʻia (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Na Mea Mekanika o ka Metala I Waihoia

| Na Mea Mekanika o ka Metala I Waihoia | |

| Rm(Mpa) | A(%) |

| ≥550 | ≥35 |

Hoʻopili

Ko makou Hale Hana

Hōʻikeʻike

ʻO kā mākou palapala hōʻoia